In today’s ever-advancing world, reliability and safety are paramount considerations across various industries. From aerospace and automotive to healthcare and manufacturing, organizations strive to minimize failures and their potential consequences. Failure Mode, Effects, and Criticality Analysis (FMECA) emerges as a robust methodology for proactively identifying and mitigating potential failure risks. In this article, we delve into the intricacies of FMECA, exploring its significance, process, and impact on overall system performance. Join us as we unveil how FMECA can revolutionize the approach to reliability and safety, maximizing efficiency and minimizing costly setbacks.

Table of Contents

Understanding FMECA

Failure Mode, Effects, and Criticality Analysis (FMECA) is a structured approach that enables organizations to proactively identify and manage potential failure risks. It builds upon the foundation of Failure Mode and Effects Analysis (FMEA) by comprehensively assessing failures and their effects.

FMECA involves a systematic series of steps, beginning with a detailed description of the system or component under scrutiny, including its functions, interfaces, and operational requirements. Next, potential failure modes are identified, which refer to specific ways in which a component or system can fail to perform its intended function.

After identifying failure modes, a team of experts evaluates their potential effects on the system, considering factors such as safety, performance, functionality, and reliability. Understanding the severity of each failure mode allows organizations to prioritize their efforts and allocate resources effectively.

The FMECA process goes beyond identification and assessment; it involves analyzing the causes and mechanisms contributing to each failure mode. This analysis helps uncover root causes and aids in developing preventive or corrective actions.

Risk assessment plays a crucial role in FMECA by evaluating the likelihood of each failure mode and combining it with the severity assessment to calculate a risk priority number (RPN) or a similar metric. This prioritization allows organizations to focus on addressing the most critical failure modes with the highest risks.

The Benefits of FMECA

Implementing FMECA brings numerous benefits to organizations:

- Enhanced Reliability: FMECA improves system reliability by identifying potential failure modes and their effects. Addressing failure risks early in the design or operational phases reduces unexpected failures, enhances uptime, and improves overall system performance.

- Improved Safety: FMECA systematically assesses the safety implications of failure modes. Understanding the potential consequences and severity of failures enables the implementation of safety measures to protect personnel, users, and the environment. This is critical in high-risk industries like aerospace, healthcare, and energy.

- Cost Reduction: FMECA helps organizations avoid costly failures and downtime. By identifying and addressing potential failure modes early, organizations reduce the likelihood of expensive repairs, recalls, or system failures. Targeted maintenance and replacement strategies optimize resource allocation and reduce unnecessary expenses.

- Compliance and Standards: FMECA assists organizations in meeting regulatory requirements and industry standards. Analyzing failure modes and their effects demonstrates a commitment to safety and helps fulfill compliance obligations.

The FMECA Process

The FMECA process involves several key steps:

- System/Component Description: Provide a detailed description of the system or component under analysis, including its functions, interfaces, and operational requirements.

- Failure Modes Identification: Systematically identify potential failure modes, considering all possible ways the system or component could fail.

- Failure Effects Analysis: Assess the potential effects of each failure mode on the system or component, considering factors such as safety, performance, functionality, and reliability.

- Severity Assessment: Evaluate the severity or criticality of each failure mode’s effects to prioritize the most critical failure modes that require immediate attention.

- Causes and Mechanisms Analysis: Investigate and identify the potential causes and mechanisms contributing to the occurrence of each failure mode. This analysis helps uncover the underlying root causes and aids in developing appropriate preventive or corrective actions.

- Risk Assessment: Determine the likelihood or probability of each failure mode occurring and combine it with the severity assessment to calculate a risk priority number (RPN) or a similar metric. This helps prioritize the failure modes for further actions.

- Risk Mitigation Actions: Develop strategies to mitigate or eliminate the identified risks based on severity, likelihood, and the calculated RPN. This may involve redesigning components, improving maintenance procedures, introducing redundancy, or implementing safety features.

- Documentation and Follow-up: Document the results of the FMECA analysis, including the identified failure modes, their effects, criticality ratings, and recommended actions. Periodically review the analysis and monitor the effectiveness of the implemented actions to ensure continuous improvement.

Implementing FMECA in real-world scenarios

FMECA has found widespread application across industries, enabling organizations to proactively manage failure risks and improve system performance. Let’s explore a few examples of how FMECA has been implemented:

- Aerospace Industry: In the aerospace sector, FMECA plays a crucial role in ensuring the reliability and safety of aircraft systems. By identifying potential failure modes in critical components like engines, avionics, and control systems, aerospace manufacturers can implement preventive measures, enhancing overall flight safety.

- Healthcare Sector: Medical devices and equipment must operate flawlessly to ensure patient safety. FMECA is employed to assess failure modes in devices such as defibrillators, ventilators, and MRI machines. By identifying potential failures and their consequences, healthcare organizations can take proactive steps to minimize risks and improve patient outcomes.

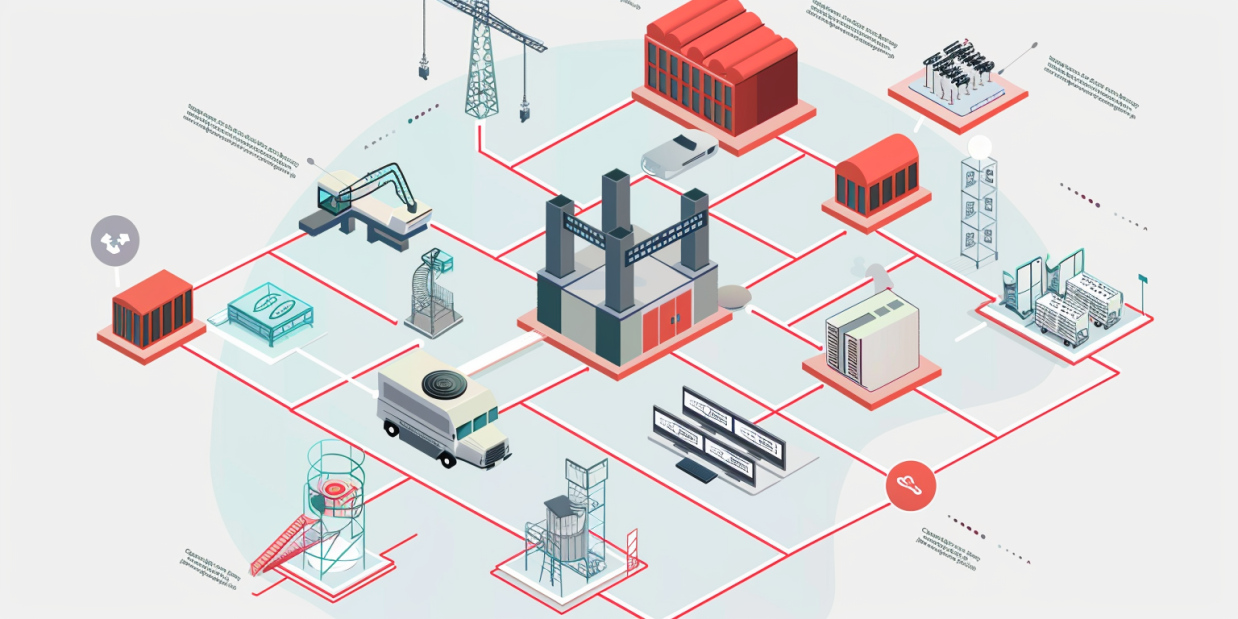

- Manufacturing Sector: FMECA is used to optimize production processes and enhance product quality in the manufacturing industry. By analyzing failure modes in machinery and production lines, organizations can identify areas prone to failures and implement preventive maintenance programs, minimizing downtime and improving productivity.

Conclusion

Failure Mode, Effects, and Criticality Analysis (FMECA) is a powerful methodology that empowers organizations to proactively identify and mitigate potential failure risks. By systematically analyzing failure modes, their effects, and criticality, organizations can enhance reliability, improve safety, reduce costs, and achieve compliance with industry standards. FMECA is applicable across various sectors, from aerospace and healthcare to manufacturing, offering invaluable insights to optimize system performance and create a safer and more reliable world. By embracing FMECA, organizations can unlock a proactive approach to managing failures and pave the way for continued success.