In the fast-paced engineering and tech world, we strive for optimal reliability, availability, and maintainability of complex systems. Here, the RAM (Reliability, Availability, and Maintainability) framework comes into play. It’s chock-full of modern tools and techniques for analysis and enhancement. This detailed article digs into RAM’s key facets, featuring the game-changing Reliability Block Diagram Analysis and the impactful Failure Mode, Effects and Criticality Analysis (FMECA). We’ll touch on the robust FRACAS (Failure Reporting and Corrective Action System) and dive into the insightful Fault Tree Analysis. By mastering these methods, we stand ready to pinpoint potential failures, refine maintenance strategies, and unlock hidden system performance potentials.

Table of Contents

- Reliability Block Diagram Analysis: Unveiling the Architecture of Reliability

- Failure Mode, Effects and Criticality Analysis (FMECA): Decoding the Language of Failure

- FRACAS System (Failure Reporting and Corrective Action System): Journeying towards Continuous Improvement

- Fault Tree Analysis: Exploring the Root Causes of Failure

- Conclusion

Reliability Block Diagram Analysis: Unveiling the Architecture of Reliability

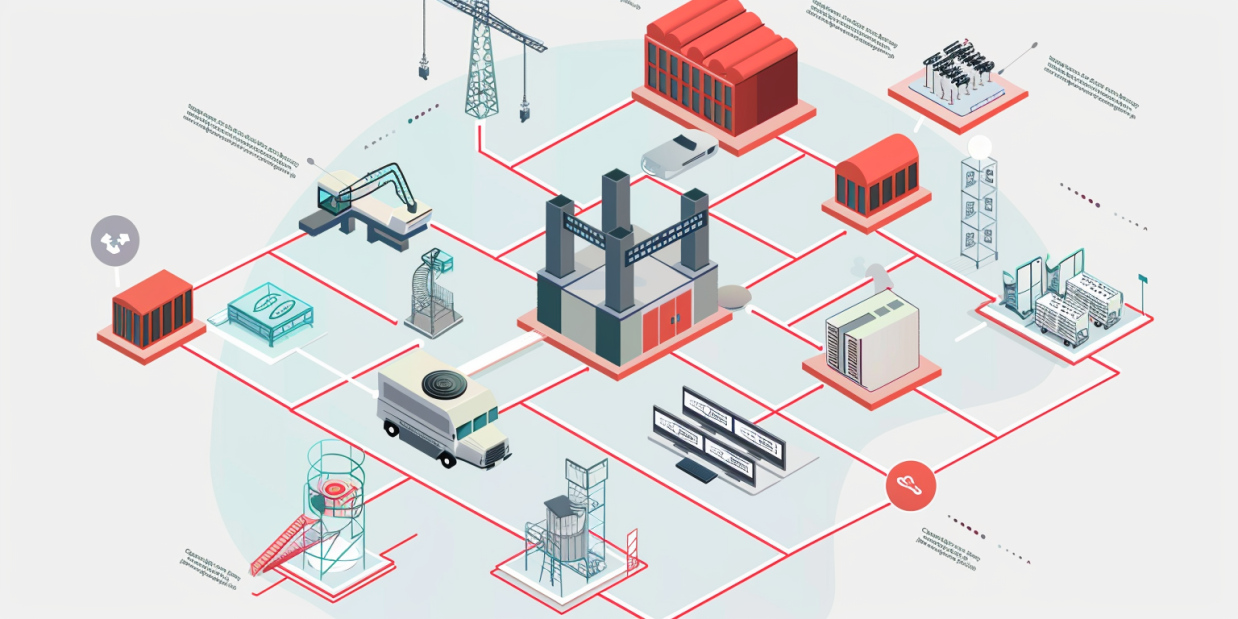

Reliability Block Diagram (RBD) Analysis serves as a potent tool to boost the robustness of complex systems. It evaluates the system as interconnected blocks, enabling engineers to spot potential failure areas. They can then gauge the impact on overall system performance and act upon targeted enhancements.

This section delves into crucial RBD analysis steps: system decomposition, block identification, failure modelling, and reliability quantification. What’s more, it underscores the advantages of RBD analysis. These include an enhanced understanding of the system, proactive failure prevention, and resource allocation optimisation.

Failure Mode, Effects and Criticality Analysis (FMECA): Decoding the Language of Failure

FMECA, or Failure Mode, Effects and Criticality Analysis, is a methodical technique dedicated to pinpointing potential failure points within a system. Assessing the results of these failures, engineers can then create strategic plans to amplify the reliability of the system, prioritising them based on their severity. This post aims to guide you through the steps in FMECA, including the identification of failure modes, evaluation of severity, estimation of occurrence, and analysis of detection. Further, it underscores the importance of FMECA in managing risks, optimising design and encouraging ongoing improvement.

FRACAS System (Failure Reporting and Corrective Action System): Journeying towards Continuous Improvement

The FRACAS (Failure Reporting and Corrective Action System) provides a robust strategy to handle system failures throughout its lifespan. It marries systematic data collection, keen analysis and swift resolution to pinpoint repeated problems, enact corrective measures and facilitate unceasing enhancement. This post delves into the critical elements of a FRACAS system, encompassing failure data recording, classification, root cause investigation, and rectification action execution. Moreover, it highlights the rewards of employing a FRACAS system, including amplified system availability, cut down maintenance expenses, and escalated client contentment.

Fault Tree Analysis: Exploring the Root Causes of Failure

Fault Tree Analysis (FTA) is a powerful tool used to analyze and understand the causes of system failures. It provides a graphical representation of the potential failure paths within a system, helping engineers identify the key events or conditions that can lead to an undesirable event. Let’s explore a relevant case study where Fault Tree Analysis played a crucial role in uncovering the root causes of a system failure.

Case Study: Power Plant Failure

Imagine a large-scale power plant that experiences a sudden shutdown, resulting in a significant loss of electricity supply to the surrounding area. The incident triggered a thorough investigation to determine the underlying causes and prevent future occurrences.

Defining the Undesirable Event

In this case, the undesirable event is the power plant shutdown, which disrupted the electricity supply.

Identifying Primary Causes

To begin the Fault Tree Analysis, engineers identify the primary causes that could potentially lead to the power plant shutdown. These causes may include equipment failure, human error, or external factors such as extreme weather conditions.

Constructing the Fault Tree

Engineers construct a fault tree by systematically breaking down the primary causes into their contributing events and conditions. Each event or condition is represented by a logic gate (AND, OR, or NOT) and connected in a hierarchical manner. For example, one branch of the fault tree could involve equipment failure as the primary cause. The contributing events and conditions for equipment failure might include component malfunction, inadequate maintenance, or operational overload. These events and conditions are connected using appropriate logic gates, reflecting their relationships.

Quantifying Event Probabilities

Once the fault tree is constructed, engineers assign probabilities to each event or condition based on historical data, expert judgment, or available statistics. These probabilities help assess the likelihood of a specific event occurring, enabling a more accurate analysis of the system’s failure potential.

Analyzing Top Event Probability

By propagating the probabilities through the fault tree, engineers can calculate the probability of the top event, i.e., the power plant shutdown. This quantitative assessment provides insights into the system’s vulnerability and helps prioritize potential mitigation measures.

Identifying Critical Contributors

Fault Tree Analysis helps identify the critical contributors to the top event. These contributors are the events or conditions with the highest impact on the system’s reliability. By focusing on these critical contributors, engineers can allocate resources effectively and implement targeted improvements.

Implementing Preventive Measures

Engineers, armed with Fault Tree Analysis findings, can actively develop preventative strategies to offset any identified failure routes. They might opt to redesign crucial components, bolster maintenance processes, better operational procedures, or put redundancies in place to shrink the possibility and aftermath of a power plant shutdown.

By harnessing the power plant case study and applying Fault Tree Analysis, engineers effectively unravelled contributory factors to the system’s downfall. Through spotting key contributors and calculating the odds of failure occurrences, they gained the necessary knowledge for deploying specific enhancements and preventative actions.

Extracting insights from the Fault Tree Analysis not only enabled the power plant to tackle the underlying cause of the shutdown, but it sparked the birth of a proactive maintenance approach to ward off future similar episodes. Continual refinement of the fault tree and updates to event probabilities based on authentic data, significantly boosted the power plant’s reliability, availability, and maintainability. This ensured a more sturdy and resilient electrical supply for the community.

The value of Fault Tree Analysis validates the effectiveness of analytical tools in disentangling complex system failures. It aids visually in mapping out events and conditions, quantifying probabilities, and earmarking critical contributors. This, in turn, empowers engineers to make educated decisions and bring into play specific enhancements to enrich system performance and dependability.

Conclusion

In wrapping it up, the engineering and technology sphere continually transforms, with the seamless operation of complex systems reliant on their reliability, availability, and maintainability. Engineers enhance system performance, mitigate risks, and spur ongoing progress by harnessing the power of RAM tools and methods. These include Reliability Block Diagram Analysis, Failure Mode, Effects and Criticality Analysis (FMECA), FRACAS System, and Fault Tree Analysis. Through comprehending these methodologies and weaving them into everyday engineering practices, professionals can proactively tackle potential failures. They can also fine-tune maintenance tactics and tap into the full potential of intricate systems. In short, employing RAM tools and methods steers a revolutionary turn in enhancing system performance and securing excellence within the engineering field.