Picture this: You’re building something that has to work perfectly 35,786 kilometers above Earth’s surface. There’s no IT help desk in geostationary orbit. No chance to pop open a panel and swap out a faulty component. Just your spacecraft, executing millions of lines of code, managing complex operations, all while hurtling through the vacuum of space.

This is the daily reality for spacecraft engineers, and it’s why they’re leading a quiet revolution in how we design and build complex systems. The traditional approach of managing spacecraft development through thousands of documents, spreadsheets, and PowerPoint presentations is giving way to something more powerful: Model-Based Systems Engineering (MBSE).

But here’s the twist – while everyone agrees MBSE is the future, making it work in practice has proven about as simple as docking with the International Space Station blindfolded. Recent research with Airbus spacecraft engineers reveals a fascinating ground truth: the path to MBSE isn’t just about better tools or fancier diagrams. It’s about fundamentally rethinking how engineering teams work together.

“The schedule is too political,” one Airbus engineer confided during a research interview, highlighting how even the best modeling tools can’t succeed without addressing the human element. Another pointed out that teams often operate in “stand-alone” mode, lacking the deep communication needed for complex spacecraft development.

Yet amidst these challenges, space teams are discovering practical ways to make MBSE work – approaches that any organization tackling complex systems can learn from. Through interviews with 25 engineers across three European countries, patterns emerged of where MBSE truly adds value and how to implement it successfully.

This isn’t just another story about the promise of model-based engineering. It’s about the real, tested ways that engineering teams are moving beyond documentation to build safer, more reliable systems. And while rockets might not be your daily concern, the lessons learned in the space industry have profound implications for anyone working on complex engineering projects.

Recommended Further Reading Amazon BooksLet’s explore how these teams are making the leap from documents to models, and what it means for the future of systems engineering…

Table of Contents

The MBSE Adoption Challenge: Why Making the Leap Is Harder Than It Looks

When Airbus engineers gathered to discuss their systems engineering challenges, a stark reality emerged: moving from documents to models isn’t just a technical transition – it’s a cultural earthquake. It’s like asking a city to switch from roads to teleporters; the destination might be better, but the journey is complex.

“The central database now offers some functionality,” one operations engineer explained, “but it doesn’t model communications passes and availability of ground stations.” This gets to the heart of the challenge: engineers need more than just new tools – they need tools that solve real problems in their daily work.

The resistance isn’t coming from stubbornness. These are, after all, rocket scientists. The challenges are deeply practical:

First, there’s the “too busy to improve” paradox. Teams are under intense schedule pressure to deliver spacecraft designs. One engineer noted that this “may produce a design that is not at the correct level of maturity.” Taking time to learn new modeling approaches feels like a luxury when deadlines are looming. It’s like trying to change engines while the plane is in flight.

Second, there’s what we might call the “interface challenge.” Different engineering teams – Operations, Software, Failure Detection, and more – speak different technical languages. As one software engineer put it, they’re facing “variable perimeter of responsibility according to the project.” Traditional documentation, for all its flaws, at least provided a common reference point.

Third, there’s the thorny issue of proving value early. Engineers aren’t seeing immediate benefits from initial modeling efforts. “The purpose for modelling must be clearly defined,” insisted one engineer. “Using models for the sake of it will not help much.” They’re right – without clear, tangible benefits, MBSE risks becoming just another corporate initiative that fades away.

But here’s where it gets interesting: these same challenges are pointing the way toward solutions. The engineers interviewed weren’t just complaining – they were outlining a path forward. They identified specific areas where models could solve real problems, from early validation of operations concepts to better communication between teams.

And some teams are already seeing breakthroughs. When models are applied to specific, high-value problems – like simulating critical mission sequences or validating system behavior early – the benefits become clear. It’s these success stories that are beginning to change minds and build momentum.

The key insight? MBSE adoption isn’t about forcing a wholesale transformation overnight. It’s about finding those critical points where models can deliver immediate value while building toward a more comprehensive transformation.

Recommended Further Reading Amazon BooksFour Key Applications that Make MBSE Worth It

When asked where MBSE could deliver real value, space engineers identified four critical areas. These aren’t theoretical possibilities – they’re battle-tested applications where modeling is already proving its worth.

1. Organization Modeling: Making the Invisible Visible

Think of organization modeling as creating a “Google Maps” for your engineering process. It shows:

🔸 Who needs what information 🔸 When they need it 🔸 How it should flow between teams

This visualization helps break down the “stand-alone behavior” that many engineers cited as a major obstacle. By mapping out responsibilities and interfaces explicitly, teams can spot potential issues before they become problems.

2. Early Functional Validation: Test Drive Your Spacecraft

Traditional approaches often mean waiting until late in development to validate system behavior. Early functional validation through MBSE changes the game:

Key Capabilities:

- Simulate critical mission sequences

- Model data flows and communication passes

- Test system initialization scenarios

- Inject failures to verify recovery procedures

3. Communication and Consistency: Speaking the Same Language

Engineers across domains need to share complex information. MBSE provides:

📋 Visual representations of functions and interfaces

📋 Clear traceability from requirements to implementation

📋 Single source of truth for design decisions

📋 Standardized notation across teams

The Impact:

- Fewer misunderstandings between teams

- Faster decision making

- Better requirement tracking

- Clearer design rationale

4. Template Model Framework: Don’t Reinvent the Wheel

Creating a template framework is like building a reusable library of best practices:

Benefits:

✓ Standardized approaches to common problems

✓ Captured institutional knowledge

✓ Faster project startup

✓ Consistent quality across projectsThese four applications share a common thread: they solve real problems that engineers face daily. They’re not about modeling for modeling’s sake – they’re about making spacecraft development faster, safer, and more reliable.

Recommended Future Learn Short CoursesPractical Takeaways: Starting Your MBSE Journey

The space industry’s experience offers valuable lessons for any organization considering MBSE. Here’s how to get started without getting lost in the cosmos.

Start Small, Think Big

Don’t try to boil the ocean. The research shows that successful MBSE adoption begins with focused efforts: one critical process, one challenging interface, or one recurring problem. As one Airbus engineer emphasized, “The purpose for modelling must be clearly defined – using models for the sake of it will not help much.”

Choose Your First Mission Carefully

Your first MBSE project needs four key ingredients for success: high visibility, clear success criteria, manageable scope, and eager team members. Think of it as a pilot mission – it should be ambitious enough to matter but contained enough to control.

Common Pitfalls to Avoid

The research highlighted three major traps organizations fall into. First is the Tool Trap – starting with technology rather than problems. Focus on what you need to solve before shopping for solutions.

Second is the Big Bang Approach. Organization-wide rollouts of MBSE rarely succeed. Instead, build confidence through small wins and scale gradually based on success.

Third is the Lonely Champion syndrome. Single advocates often burn out trying to drive change alone. Build a coalition of supporters that includes both management and engineers.

Measuring Success

Success in MBSE adoption isn’t just about having models – it’s about solving problems. Track meaningful metrics like time saved in design reviews, reduction in integration issues, earlier detection of problems, and team adoption rates.

The Human Factor

“Models themselves can be the new language,” noted one Operations Engineer. This captures a crucial truth: MBSE is as much about people as it is about technology. Training is essential, resistance is normal, and success stories matter. Most importantly, clear communication throughout the process is key.

The journey to MBSE may be long, but it doesn’t have to be painful. The key is to start with clear problems, build momentum through success, and keep the focus on delivering real value. Organizations that follow this path can make the transition while keeping their existing projects on track.

| Challenges | Traditional Approach | MBSE Solution | Implementation Tip |

|---|---|---|---|

| Operations Concept Validation | Wait until late phases to validate mission sequences | Early simulation of critical operations (deployment, initialization) | Start with one critical mission sequence to validate approach |

| Multi-team Communications | Document-based interfaces between Operations, Software, and FDIR teams | Unified model serving as single source of truth | Begin by modeling interfaces between just two teams |

| Data Flow Management | Spreadsheets tracking telemetry, commands, and ground station passes | Integrated data flow models with timing analysis | Focus first on highest-risk data flows (e.g., critical commands) |

| System Initialization | Text-based procedures with limited validation capability | Executable models of startup sequences with failure injection | Model nominal startup first, then add failure cases |

| Requirements Traceability | Manual cross-referencing across documents | Automated tracing from requirements to implementation | Start with one subsystem’s requirements to demonstrate value |

| Knowledge Transfer | Reliance on expert knowledge and historical documents | Reusable model templates capturing best practices | Document one successful pattern as initial template |

| Cross-site Collaboration | Multiple document repositories across locations | Shared model database with controlled access | Begin with small pilot between two sites |

| Interface Management | Interface Control Documents requiring manual updates | Model-driven interface definitions with consistency checking | Model one critical interface end-to-end |

Key Takeaway: Space teams found most success starting with focused, high-value applications rather than attempting comprehensive MBSE implementation immediately. Each solution above can serve as an entry point, depending on your organization’s specific pain points.

Conclusion

The journey from documents to models isn’t just about better engineering – it’s about survival in an increasingly complex world. As spacecraft systems become more sophisticated and missions more ambitious, the old ways of working simply can’t keep up.

The research from Airbus tells an important story. While engineers acknowledge the challenges of adopting MBSE, they also see its inevitability. One engineer put it well: “The central element would be the model database.” Not might be, but would be. The question isn’t whether to adopt MBSE, but how to do it effectively.

Three key insights emerge from the space industry’s experience:

First, successful MBSE adoption is about solving real problems, not following trends. The most successful implementations start with engineers’ actual pain points – whether that’s validating operations concepts earlier or improving communication between teams.

Second, the human element matters as much as the technical one. The best model in the world won’t help if teams don’t use it. Building trust, showing value, and creating a shared language are crucial steps in the journey.

Third, the benefits of MBSE compound over time. As teams build reusable components and capture best practices in their models, each new project becomes more efficient than the last. It’s an investment that pays continuing dividends.

Looking ahead, the space industry’s experience with MBSE offers a preview of where all complex engineering is heading. The days of managing spacecraft development through disconnected documents are numbered. The future belongs to those who can effectively harness the power of models to manage complexity, improve communication, and deliver better systems.

For organizations still watching from the sidelines, the message is clear: the time to start the MBSE journey is now. Start small, focus on value, and build momentum through success. The road may be long, but as the space industry is showing, it’s well worth the journey.

After all, if MBSE can help engineers send spacecraft to Mars, imagine what it could do for your next project.

References

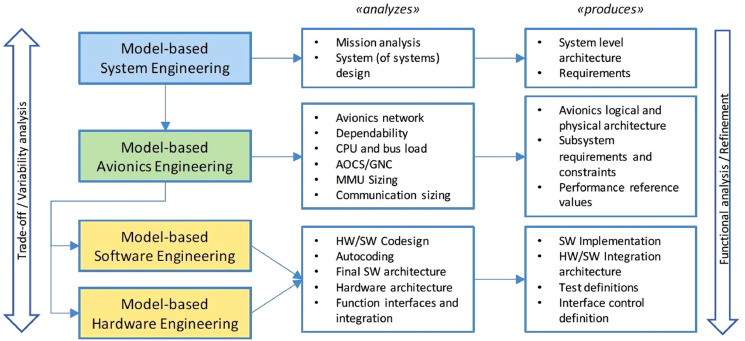

- Gregory, J., Berthoud, L., Tryfonas, T., Rossignol, A., & Faure, L. (2019). The long and winding road: MBSE adoption for functional avionics of spacecraft. Journal of Systems and Software.

- Bone, M. A., & Cloutier, R. (2009). The current state of model based systems engineering: Results from the OMGTM SysML request for information 2009. In Proceedings of the 8th Conference on Systems Engineering Research.

- Madni, A. M., & Sievers, M. (2018). Model‐based systems engineering: Motivation, current status, and research opportunities. Systems Engineering, 21(3), 172-190.